The Cost Dynamics Of Custom Patch Production

Patches, those ubiquitous emblems of identity and affiliation, are more than mere pieces of fabric; they are symbols that carry the weight of history, loyalty, and pride. Whether adorning the uniforms of military units, the jerseys of sports teams, or the jackets of motorcycle clubs, patches serve as visual representations of shared values and belonging. However, behind their seemingly simple appearance lies a complex process of creation, one that involves meticulous craftsmanship, attention to detail, and, inevitably, cost.

When considering the expense involved in producing custom patches, it’s essential to delve into the intricacies of the manufacturing process. Each step, from initial design conception to final product delivery, carries its own set of challenges and expenditures. Let’s take a closer look at the various factors that influence the cost of patch production.

Design Complexity

At the heart of every patch lies its design—the visual embodiment of a brand, a message, or an idea. The complexity of this design plays a significant role in determining production costs. Intricate artwork with fine details and multiple colors requires more time and labor to replicate accurately. Each stitch must be carefully planned and executed to ensure fidelity to the original design, driving up the overall cost of production.

Size Matters

Size is another critical factor that impacts patch manufacturing costs. Larger patches not only require more fabric but also demand greater attention to detail during the stitching process. A larger canvas provides more space for intricate designs, but it also necessitates a higher level of craftsmanship to maintain clarity and precision. As a result, larger patches tend to incur higher production costs compared to their smaller counterparts.

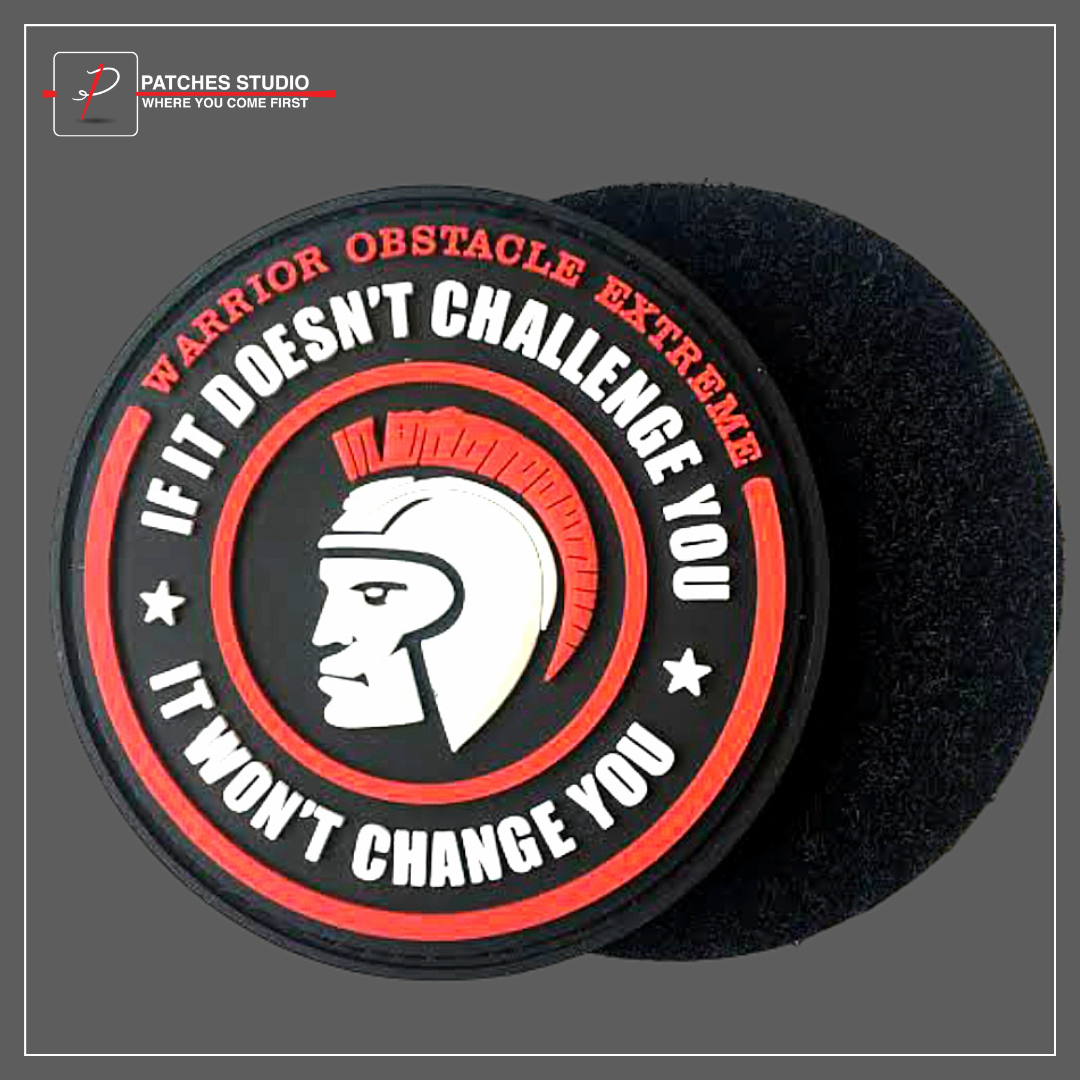

Type of Patches

The type of patch chosen—whether embroidered, woven, printed, or PVC—also influences production costs. Each type has its own unique production method and associated expenses. Embroidered patches, with their tactile texture and three-dimensional appearance, are a popular choice for many applications. However, alternatives such as woven patches or printed patches may offer cost savings for simpler designs or larger quantities.

Quantity Discounts

Ordering patches in bulk can yield significant cost savings due to economies of scale. Many manufacturers offer tiered pricing based on the quantity ordered, with per-unit costs decreasing as the order size increases. This incentivizes customers to place larger orders, thereby streamlining production and reducing overhead costs per patch. By taking advantage of quantity discounts, customers can maximize their budget and obtain a higher volume of patches for their investment.

Material Quality

The quality of materials used in patch production also affects costs. Higher-quality fabrics and threads command higher prices but offer superior durability and aesthetic appeal. Investing in premium materials ensures that patches withstand the rigors of everyday use and maintain their vibrant colors and crisp details over time. While cheaper alternatives may offer short-term cost savings, they often result in inferior patches that fail to meet quality standards.

Customization Options

Additional customizations, such as backing options (iron-on, Velcro, adhesive), special borders, or embellishments, can add to the overall cost of patch production. These optional features provide added functionality or visual appeal but come at an additional expense. Customers must weigh the benefits of these customizations against their budgetary constraints to determine the most cost-effective solution for their needs.

The Complexities Of Patch Pricing

In light of the numerous variables involved in patch production, navigating the intricacies of pricing can be daunting. That’s where the expertise of industry professionals becomes invaluable. With years of experience in crafting high-quality patches for a diverse range of clients, we are equipped to guide customers through the process of selecting the optimal design, materials, and production methods to achieve their desired outcome within their budgetary constraints.

By leveraging their expertise and industry connections, we ensure that customers receive exceptional value for their investment, with no compromise on quality or craftsmanship. From initial concept development to final product delivery, their team of skilled artisans works tirelessly to bring each design to life with precision and care. Whether you’re a small business owner looking to create branded merchandise, a sports team seeking to unite your players under a common emblem, or an individual commemorating a special event or milestone, we are committed to exceeding your expectations every step of the way.

In conclusion, the cost of producing custom patches is influenced by a multitude of factors, ranging from design complexity and size to material quality and customization options. While navigating these variables can be challenging, partnering with a reputable manufacturer ensures that customers receive the highest level of quality, affordability, and expertise throughout the production process. By understanding the intricacies of patch pricing and leveraging the guidance of industry professionals, customers can achieve their desired outcomes while maximizing the value of their investment. Whether you’re looking to create a single patch or a large batch for distribution, we are your trusted partner in bringing your vision to life with precision, passion, and professionalism.